I’ve been doing a lot of coding for the arduino control of the camera Im calling OX2.

I was considering porting the whole thing over to a RPi so that I could have a keyboard and screen etc to allow more functions based on prompts etc. But seeing as all I need is a X230/IBM or something smaller even, its possible to imagine using this system with the serial monitor?

Instead of writing code and building all the hardware to offer all the functions I’m just using the arduino in PC-usb connected mode and using the serial monitor to do the operation.

After quite a few rewritings Ive landed on a nice set up that offers the following:

1. Single frame always on button.

2. F for forwards and R for reverse camera direction.

3. Select 16 or 35mm, used to instruct footage counter which differs between the guages, ie 40 and 16 frames respectively.

4. Input nunber of frames. Ie, 1 = 1 frame, 24 = 24 frames.

5. B setting, asks for time open in seconds, ie 20 = 20 seconds.

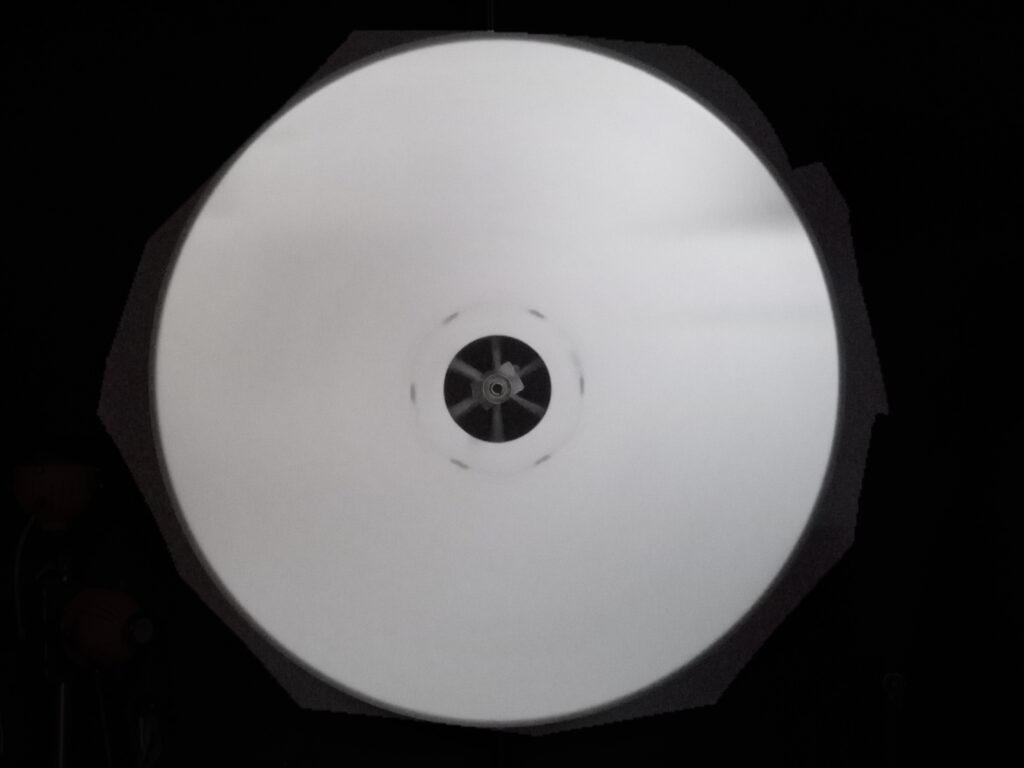

6. H function opens shutter 180 degrees, effectively going into ROTOSCOPE mode. This is very useful for setting up camera-projection.

7. Counters for ‘session’, or lifetime (magazine footage). With resets on both.

TO DO:

8. Speed of steps monitor. The effective shutter speed is best measured ITRW. This is because the maths doesnt really add up. You need to high speed video the mech running in rotoscope mode, and measure the frames in an edit programme. I use Vegas. If the POT input (which controls speed) is mapped to ACTUAL shutter speeds we can use this for displaying shutter speeds in the future.

9. Micro step mode. This is useful if there develop problems with shutter sync. This can and has happened. Despite the motor being closed loop, it doesnt actually have an exact position sensor. You could add one, but the drive is built tightly into mounting hardware and the shaft is not accessible.

10. Getting Arduino to pulse out frame counters for big red LED displays. Note to self, the memory counter can only be volt free, ie fired from a relay.

11. Emergency STOP function if you type in too many frames. This could also go on the big red stop button on the controller.

12. Trigger motion-control job/event. I know I will get around to this, but if we employ simple (and inexpensive) CNC X & Y moving stages for movement of objects we have basically a Go-Motion rig.

13. Time Lapse. This will be easy enough, but be better employed if the whole rig is portable, ie to take outside, and need to build the 36v psu for this and work out way to power TUPS.

14. More a question. Has stepper micro setting been fully explored? Is 1600 per rotation absolutely the best setting?