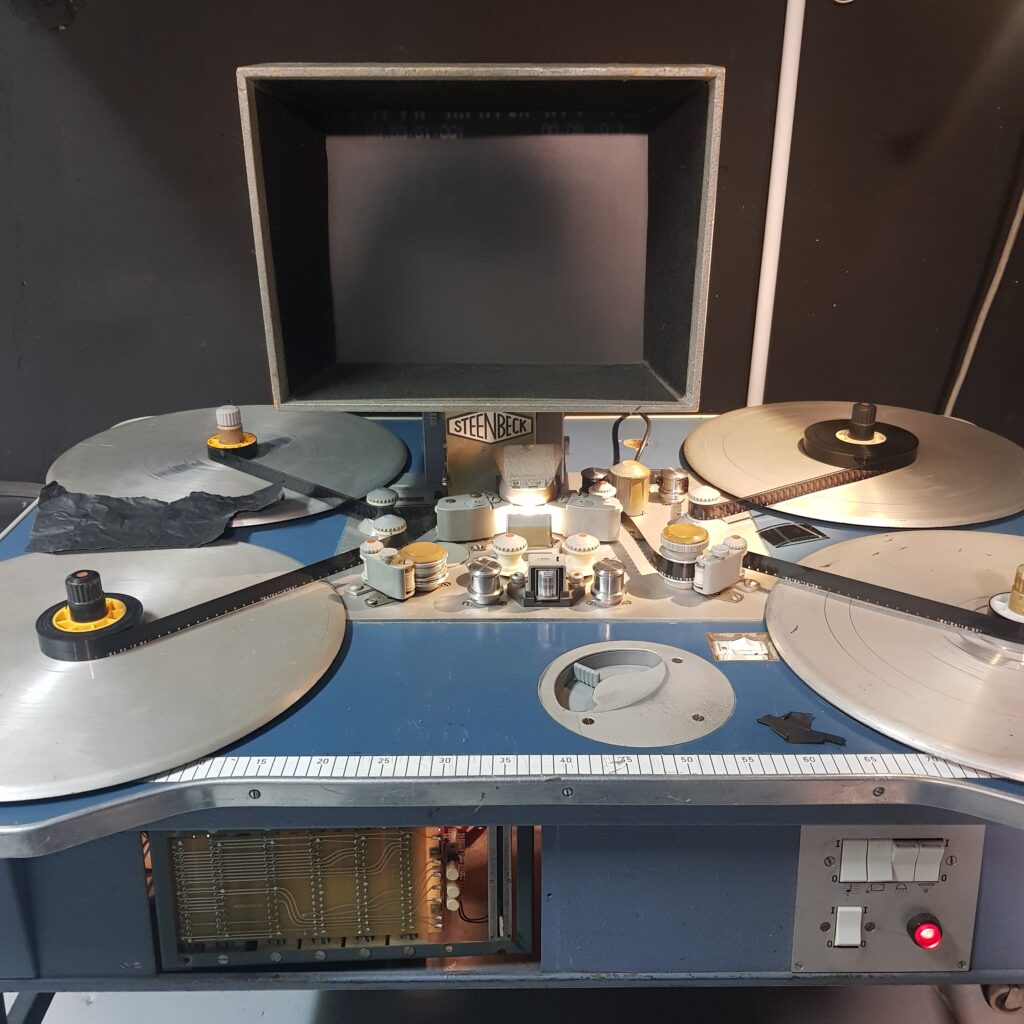

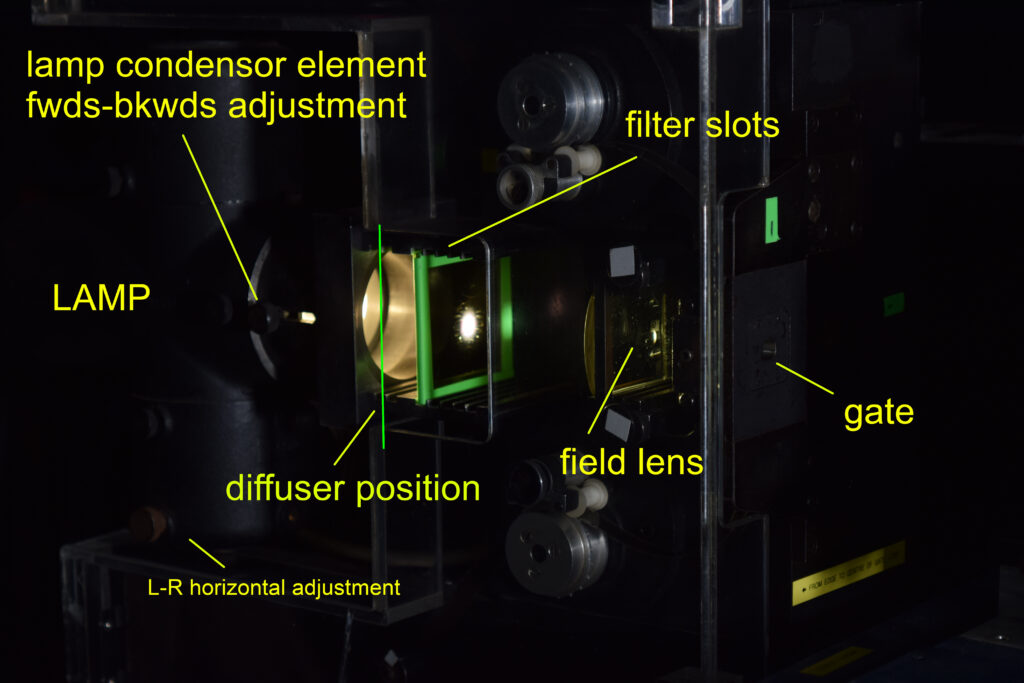

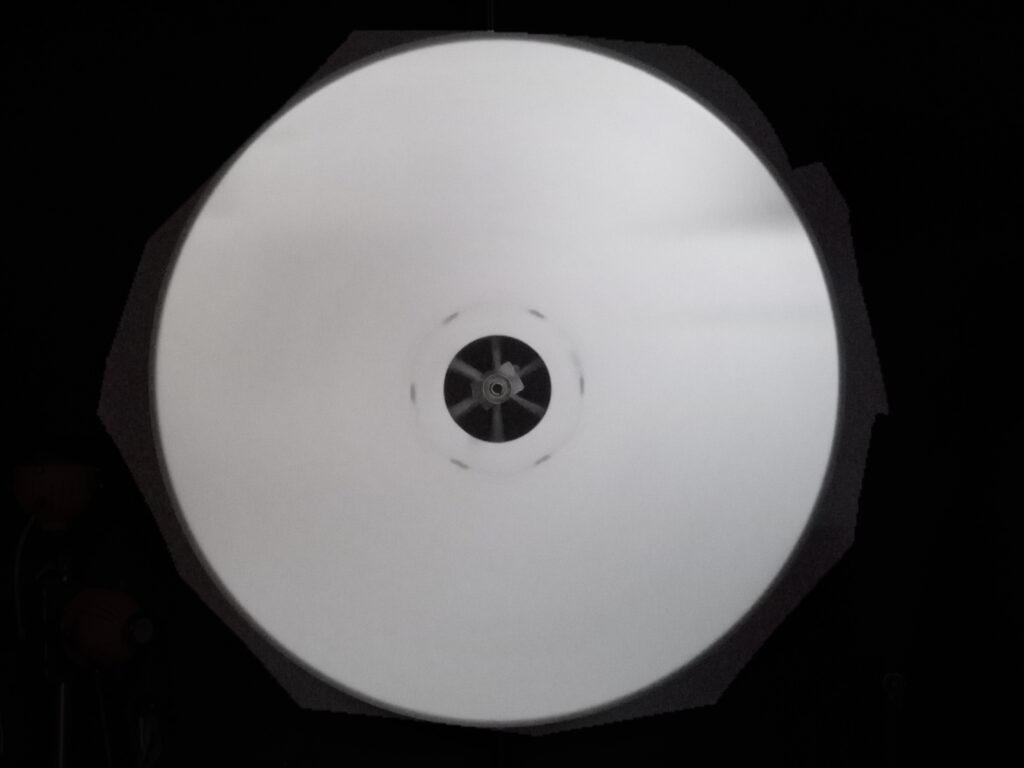

It is well known that flat table editing machines can be modified into contact printers. All that needs to be done is to black out the screen and any light leaks from the cabinet. Make somekind of slit that covers the prism and mask off any light straying out from the prism block. You then load your neg on the mag-stock platters and through the image gate and your raw stock following the usual film path. Emulsion to emulsion. The light passes up through the prism, through the slit, through the neg, through the raw film.

The two sprocket drives need to be engaged so the films run together. Ill document the gate assembly here as it will involve some engineering and adjustable slits. Just changed the fan in this machine. All I need to make it FWO is a new optical sound head. Lew!!!!